The subject of the study was to check the differences in UV resistance of sublimation and resin printing. Two Octa

Optima 3 x 3 m tents with 100% printing were set up for this purpose. The roofs of the tents were made of impregnated

polyester fabric of a weight of approximately 200 g/m², customarily used by the MITKO company to manufacture

tents and advertising umbrellas. One roof was printed with transfer sublimation technique and the other with resin

printing technique.

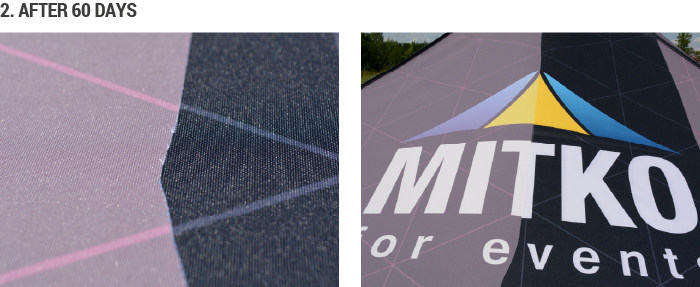

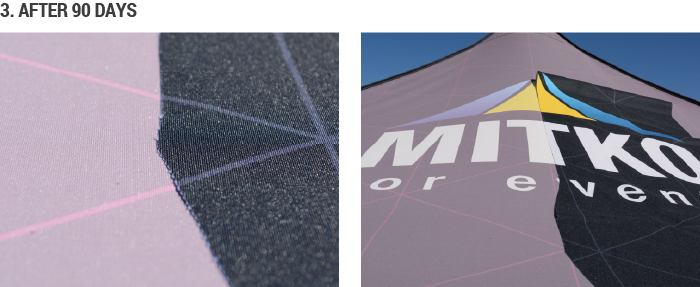

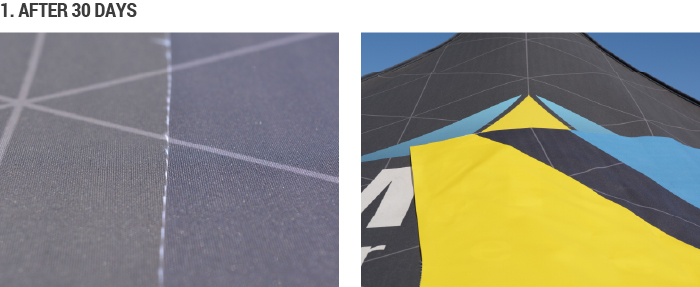

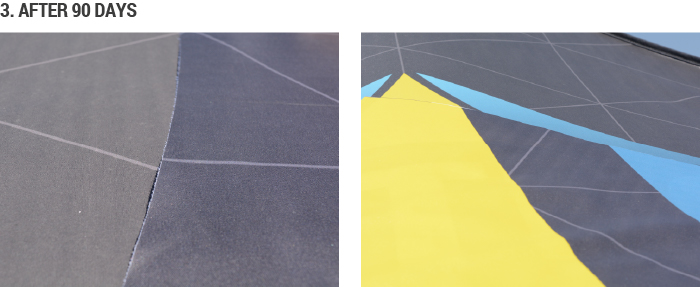

From 8. 06 to 8. 09. 2021, the tents were subjected to continuous UV exposure. Colour saturation every 30 days was

compared to unexposed standards.

As a result of the test, it was found that after 90 days of uninterrupted exposure to sunlight, the Delta E parameter

of the dominant black colour for sublimation printing compared to the standard was 26,3. The Delta E of the dominant

black colour for the resin print relative to the standard was 3, 5.

The numerical value of the Delta E parameter approximately describes the color difference as follows:

0.0 –1.0 – imperceptible difference (often measurement error)

1.0 – 2.0 – people with high colour sensitivity (women, artists, etc. ) can see the difference

2.0 – 3.0 – noticeable colour difference

3.0 – 6.0 – difference acceptable in digital printing process

6.0 – >> – large colour difference noticeable to most people

The MITKO company recommends the resin printing technique for printing products exposed to permanent and

strong UV radiation, especially advertising umbrellas.

Click the star to rate this article

Avg. rating: 5/5. Rated: 4